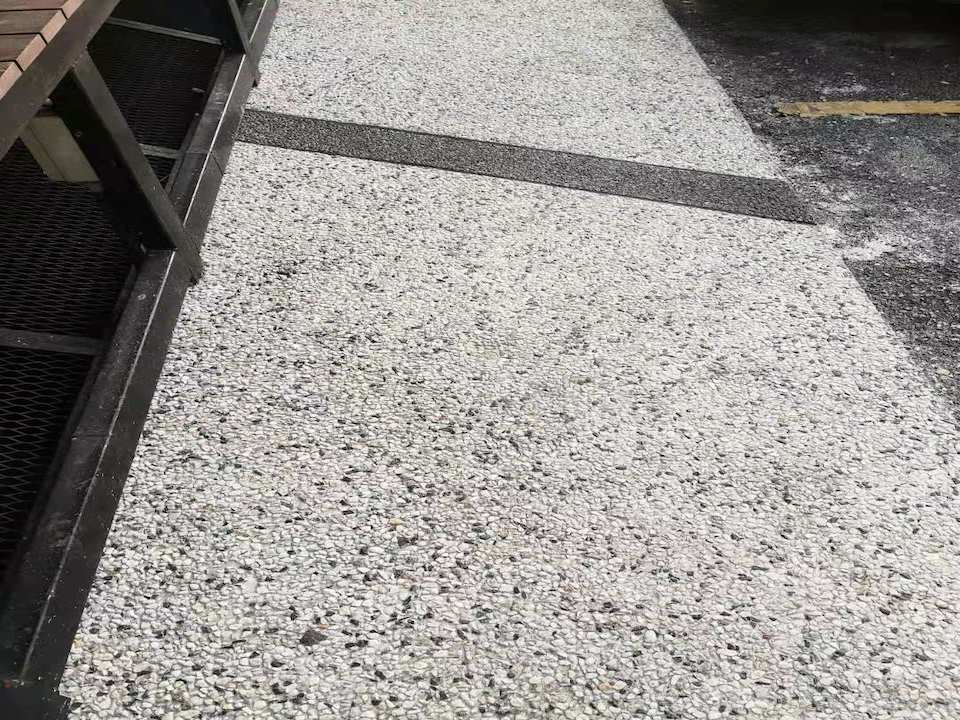

As the name implies, exposed aggregates flooring is a concrete or cement floor finishing in which the aggregates on the surface are revealed, these would be otherwise concealed by the thin layer of cement paste. Exposed aggregates flooring is among the earliest and the most popular decorative concrete flooring in use for over hundreds of years. Still, it never goes out of fashion and offers a timeless appearance with many other practical advantages such as anti-skidding property, easy maintenance, least expensive and unlimited possibilities in aesthetic appearance due to the vast choices of aggregates selection.

We make the above floor finishing possible by offering our newly formulated FormCrete Exposed Aggregate Surface Retarder to retard the setting of cement on the freshly laid concrete or cement surfaces for a period of 14-20 hours hence allowing the un-set cement paste to be washed away by means of a water jet thus revealing the beautiful aggregates beneath.